Innovation Takes the Lead: Ford and the Academies of Louisville Build the Future Workforce

"We don’t have enough skilled trades people. We don’t have enough of the right people for the skills we need for the future," noted Ford Motor Company employee Ed Combs at the recent Ford-JCPS Sprint finale. In an era when industry leaders acknowledge the urgent skills gap, this three-month intensive challenge put Academies of Louisville engineering students in direct consultation with top Ford professionals, proving that the next generation of industrial problem-solvers is already here.

“My biggest takeaway is that fresh perspective is huge,” observed Galen Mansoor, Innovation Engineer with the Ford Manufacturing Technology Development Center, as the student presentations concluded. The recent culmination saw students from Jeffersontown High School and Fern Creek High School present sophisticated technical solutions to a distinguished panel, including VP-Human Resources Adam Yeloushan and Senior Director Johanna Shea.

This high-level engagement demonstrated Ford's commitment to nurturing local talent while solidifying a shared vision with the JCPS Academies of Louisville for innovation and hands-on skill development in advanced manufacturing careers.

A Shared Vision: Innovation Across the Academies

The foundation of this partnership began not just with a corporate need but with a strong vision championed by Ford's North American Innovation Team. Mansoor explained that his manager, Liz Bullard, recognized a critical gap in the workforce pipeline and a corresponding untapped resource: the talented students living right next to Ford's massive Louisville facilities.

"It really began with Liz, my boss, having a conversation with somebody from Ford Next Generation Learning (NGL)," Mansoor explained. This strategic alignment with the Ford NGL model—which promotes career-focused high school education and community involvement—helped Ford localize the effort in Louisville.

"We recognized that a lot of the students local to our giant facilities out here...really had little to no exposure to what actually goes on in the manufacturing plants," said Mansoor. The goals were clear: leverage the local talent pipeline, ensure these students knew about the vast career opportunities at Kentucky Truck Plant (KTP) and Louisville Assembly Plant (LAP), and showcase the innovation within modern manufacturing.

The Academies of Louisville, launched in 2017 and now in its ninth year of implementation within Jefferson County Public Schools (JCPS), ensures that every student is trained with the lens of innovation and professional problem-solving, regardless of their ultimate career destination. This robust structure has transformed large high schools into agile learning communities, encompassing 15 wall-to-wall career academies.

Supported by over 230 business partners, this approach empowers students to apply academic knowledge to real-world challenges, a critical skill set for modern industry. The results are compelling: JCPS has seen a 30% increase in the number of students who graduate college and/or career ready, equipping them not just with a high school diploma, but also with industry-recognized certifications, post-secondary credit, and valuable professional experience.

For instance, the Build and Design Academy at Jeffersontown High School fosters innovation in engineering and welding, while the Business and Health Science Academy applies the same problem-solving rigor to fields like Financial Services and Patient Care. Similarly, Fern Creek High School develops technical talent in pathways like automation engineering and computer science, connecting them with fields that require complex systems thinking.

This foundational exposure to collaborative, project-based work ensures students are not just learning technical facts but are developing the agile mindset required to tackle multidisciplinary challenges, making them perfect partners for a fast-paced "sprint" environment.

The Solutions: Real-World ROI

Ford presented the Academies of Louisville students with genuine, quantifiable challenges directly impacting the bottom line and employee well-being at KTP and LAP. These projects demanded more than textbook answers; they required innovative solutions that provided immediate Return on Investment (ROI) and measurable improvements in employee health and safety.

The intensive, three-month timeline demanded extraordinary focus from the students. The process kicked off with a critical field trip on September 9, where students visited either KTP or LAP to see the facilities and to understand the problem firsthand. Throughout the sprint, teachers Dr. Aldo McLean (Fern Creek) and Jason Stepp (Jeffersontown) guided the project development, supported by weekly check-ins with Ford mentors. Ford professionals demonstrated further dedication by making in-person visits to the schools. This dedicated effort culminated in the final presentations on November 18.

1. KTP Design Solution: Solving the Quality Crisis

Partnering with KTP, the Jeffersontown students faced a costly quality control issue: "chip and scratch" damage caused by DC tooling, resulting in nearly $200,000 in annual rework.

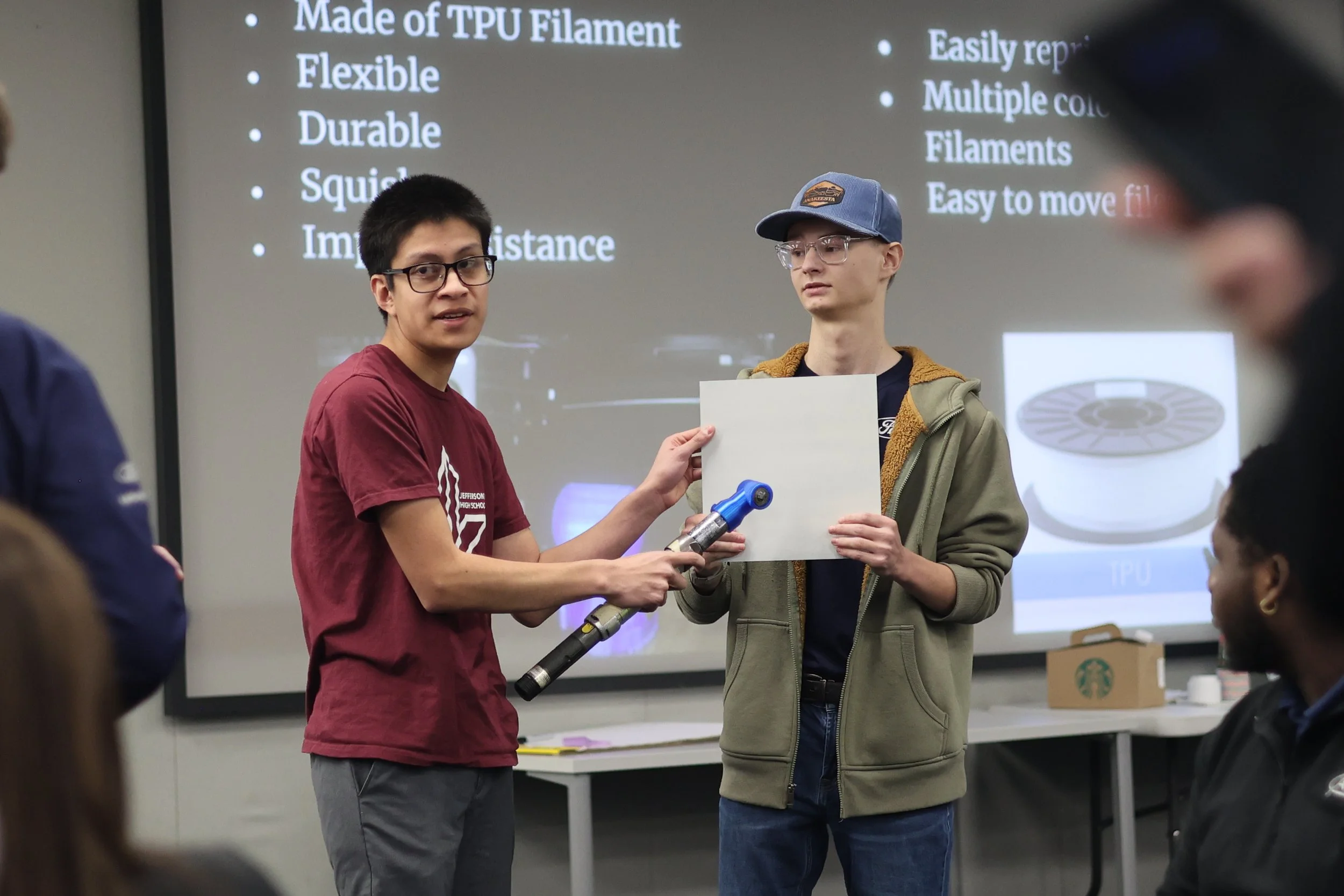

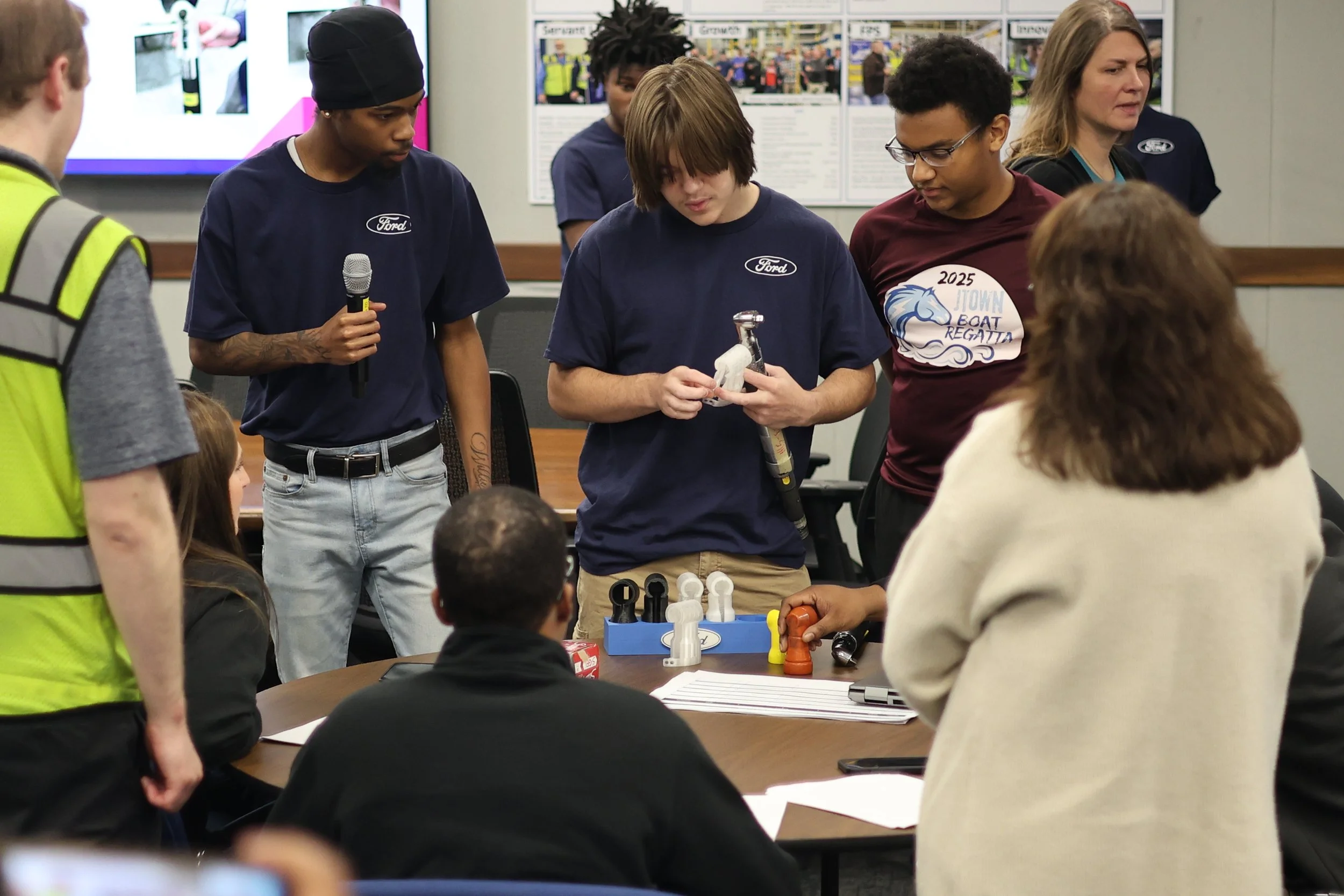

The winning team didn't just propose a fix; they engineered a solution. Utilizing their skills in CAD and 3D printing, they designed a durable, reusable tool cover made from Thermoplastic Polyurethane (TPU) filament. This flexible design, achieved through intensive prototyping, directly replaced the wasteful, single-use covers and provided a superior design that prevents damage.

"The complexity of the problems and the determination [were impressive]," noted Regional Director Joe Closurdo, observing how students quickly leveraged design skills to reduce material waste and improve quality control across the assembly line. Jamal McFarland, Vehicle Evaluation Manager, added, "The growth has been really good from the day you guys came here to today, so I’m excited," highlighting the transformation achieved through intense trial-and-error in their design process.

2. LAP Logistics Solution: AGV Optimization and Ergonomics

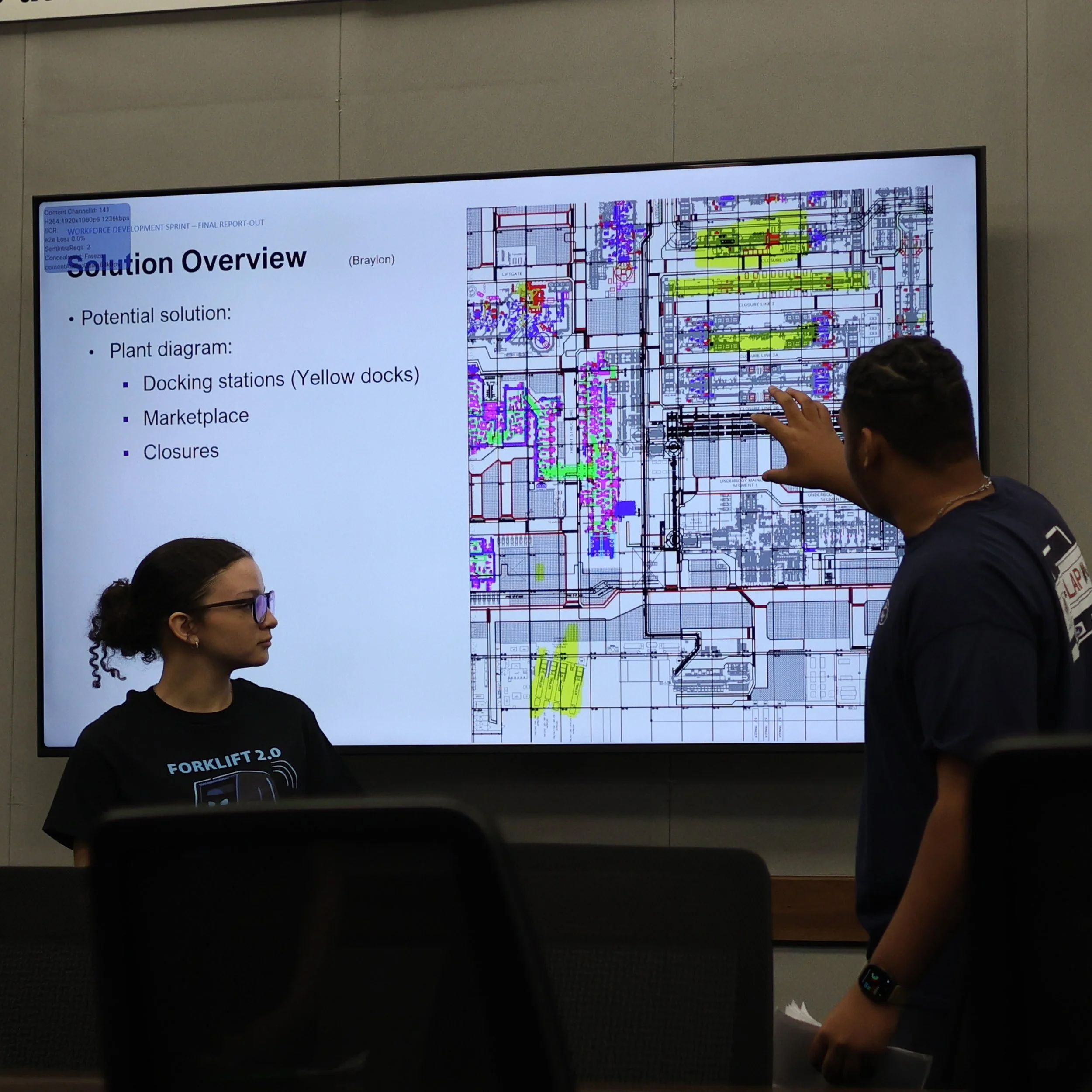

The Fern Creek teams collaborated with LAP to overhaul material flow logistics. Their focus was human-centric innovation: minimizing the ergonomic strain on forklift operators while simultaneously improving assembly efficiency.

The students’ innovative solution was a rigorous ROI analysis for deploying Automated Guided Vehicles (AGVs). Applying systems thinking and data analysis, they proved that AGVs could operate 24/7, deliver safer, more consistent material flow, and effectively replace manual forklifts on high-repetition routes. This strategic shift frees up human employees for higher-value, specialized tasks, demonstrating that automation is not about replacement, but employee empowerment.

Doug Cramer of LAP praised the depth of their analysis, noting he was "relieved to see the journey. Where we started to where we’re going to end up is exciting."

Pathways to Success: Life Lessons and Future Careers

While the competition ultimately produced winning teams, the true reward of the Ford-JCPS Sprint was the invaluable professional skill development achieved by every student. The final component of the day, a candid career panel featuring Ford professionals from Skilled Trades, Data Science, and Engineering, reinforced a critical message: the soft skills forged in this intense project are the ultimate career currency.

Students found that the abilities required to navigate the sprint—far beyond the technical specifications—were the most transformational:

High-Stakes Experience: "You’re getting challenged by something you would never expect to get, work that not even an intern for Ford would get," said Fern Creek student Alisant, perfectly encapsulating the high stakes of the experience.

Communication and Teamwork: "We had to communicate a lot. One small difference can change the whole thing," said Fern Creek student Angel, emphasizing how collaboration overcame the technical difficulties of pathfinding and data gathering.

Confidence and Public Speaking: Many students cited overcoming anxiety as a major takeaway. Caitlin, a J-Town student, shared that due to her social anxiety, the sprint was "a good opportunity for me to overcome my fear of talking in front of people." This growth was mirrored by Joshua, a Fern Creek student, who noted how the experience helped him: "This really helped with forming those words where I don’t stutter as much. And this is one of the major presentations I had... where I get to talk to somebody who is higher up in management."

Defining Purpose: Students learned that problem-solving applies everywhere. "I think the biggest thing that I learned from this project was teamwork... but we got it done at the end of the day, and I think that’s all that matters," shared Jacob from J-Town.

Project Management and Collaboration: Hailey, a Fern Creek student, explained the structured team effort: "The beginning was really a big collaboration of everyone... and then, after we split into our two separate groups, we started digging deeper and collaborating with just our groups individually." This highlighted the essential process of initial brainstorming, focused delegation, and sustained group work.

By collaboratively translating factory floor challenges into academic projects, Ford Motor Company and the Academies of Louisville are not just celebrating innovation by actively building a future workforce that is highly skilled, industry-ready, and eager to drive America’s manufacturing sector forward. The growth in communication, professional agility, and complex problem-solving directly addresses the critical skills gap noted by Ford leaders, proving that these students are the solution to the industry's future talent needs.

McFarland underscored the lasting career impact of the sprint: "Don’t let this be the last time you talk about this assignment. If you speak anywhere about that [capstone project], you’re going to get hired." This is the tangible proof of concept for the Academies of Louisville mission: transforming student potential into industry success.